Environment

1

2

3

4

5

6

7

8

Investments and

environmental expenses

COP 1.2 trillion

in environmental management,

increase of 25%

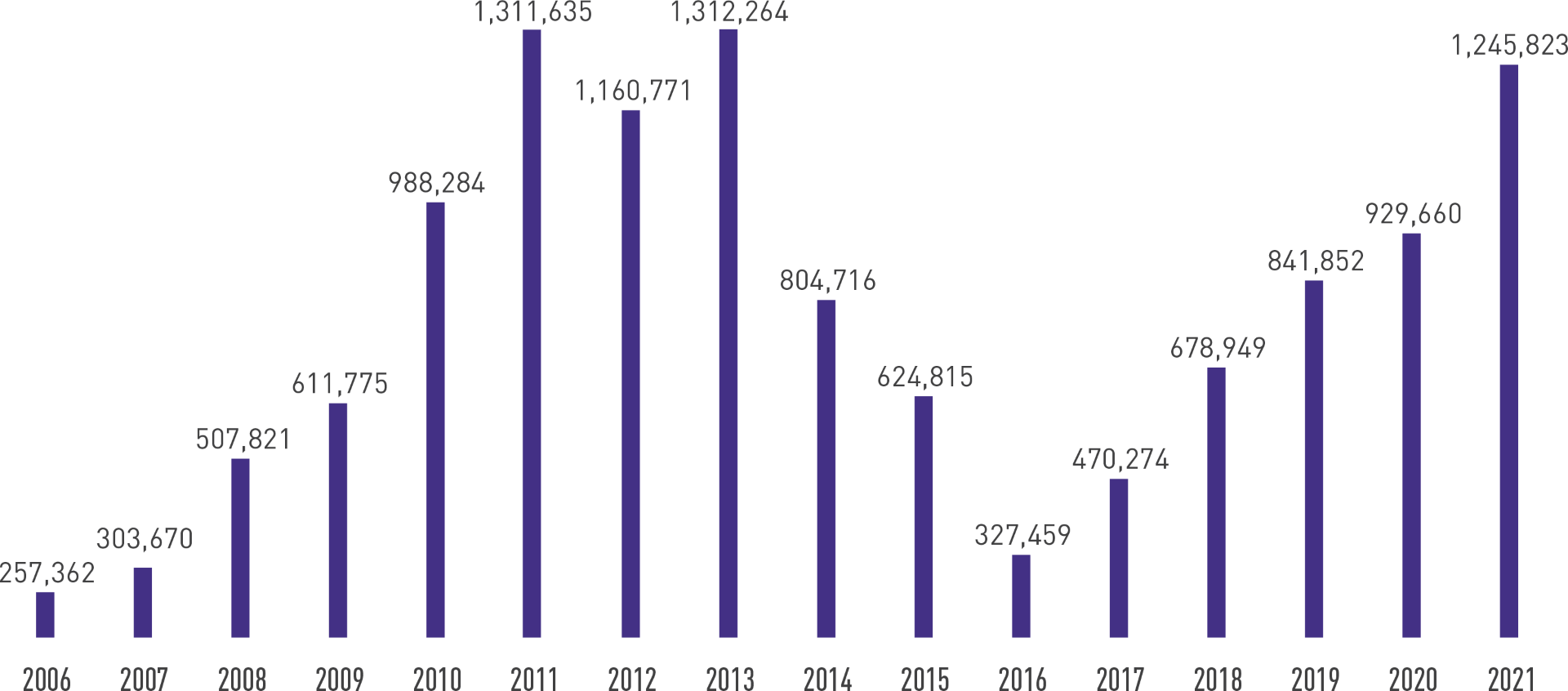

Environmental investments and expenses at Ecopetrol S.A. (Millions of pesos)

COP 116,089

billion

mainly allocated to environmental activities, environmental education, the dissemination of environmental activities, the hiring of environmental management personnel, environmental studies, and legal procedures, as well as the operation and maintenance of equipment and monitoring networks.

COP 35,950

billion

billion for the management of natural water resources, allocated to related recovery and protection programs, the purchase and assembly of equipment to control and monitor the quantity and quality of surface and/or underground water resources, and the protection of water basins.

COP 21,703

billion

for the recovery and protection of forests.

COP 271,473

billion

for the recovery and protection of natural air resources, allocated to the acquisition of equipment and the development of productive technologies to reduce atmospheric emissions.

COP 223,582

billion

for the recovery and protection of soil natural resources, allocated to the management and physical works for soil protection (geotechnical protection measures).

COP 15,159

billion

in biodiversity, allocated to biodiversity preservation and conservation projects.

COP 450,367

billion

in drinking water and basic sanitation, allocated to wastewater treatment projects, construction and implementation works for drinking water supply, and the management and disposal of solid and hazardous waste.

COP 111,646

billion

in risk management, allocated to disaster prevention management and support in disaster response.

Environmental

planning and compliance

Ecopetrol S.A. currently holds

402 environmental authorizations

issued by national and regional environmental authorities, distributed as follows:

Environmental authorizations issued

| Business segment | Environmental Licenses / Environmental Management Plans / Environmental Management Measures | Permits for the use and exploitation of natural resources |

|---|---|---|

| Exploration | 53 | 3 |

| Production | 111 | 219 |

| Refining | 3 | 9 |

| Other | 0 | 4 |

In 2021, Ecopetrol received 3,680 administrative acts issued by the Environmental Authorities, of which 1,548 contained systematic monitoring requirements at the strategic, tactical, and operational levels to ensure timely compliance with the obligations set forth by said authorities.

Prior to managing and obtaining environmental authorizations, Ecopetrol S.A. conducts activities to understand and diagnose environmental aspects and determinants during the project planning stage. Thus, it identifies the potential environmental impacts and the essential opportunities to design and plan the environmental management measures established based on the mitigation hierarchy.

The following environmental authorizations were obtained in 2021

- 18 environmental authorizations from ANLA by means of the legal channel known as minor changes.

- One (1) Environmental License issued by ANLA for “the construction and operation of the Vasconia – Teca gas line”.

- One (1) Modification of the Environmental License under Resolution 1257 of 2015 for Exploratory Drilling Area VMM32.

- Two (2) Modifications of Comprehensive Environmental Management Plans (PMAI, by its Spanish acronym) under the projects “Inclusion of gas variant 4”, “Sogamoso Yariguí – Cantagallo Bridge,” and “Pilot plan for water injection and wastewater disposal at the Palagua field”.

- One (1) Subtraction of the Magdalena River Forest Reserve, created by Law 2 of 1959, for the “Yariguí 3D Seismic” project.

- One (1) establishment of environmental management measures for the Apiay – Chichimene transfer line.

- 53 environmental authorizations were obtained from Regional Autonomous Corporations (CAR, by its Spanish acronym) for the use and exploitation of natural resources at Ecopetrol S.A. fields.

In addition, 132 procedures were managed and filed with the Regional Environmental Corporations (CAR for its Spanish acronym), the Ministry of Environment and Sustainable Development, and ANLA.

Compensation for the use of natural resources and

compulsory investment of not less than 1% in the water basins

subject to capture

Compliance with environmental obligations arising from the use and exploitation of natural resources and the collection of water from watersheds is established in control and monitoring instruments (environmental licenses, environmental management plans, and environmental permits).

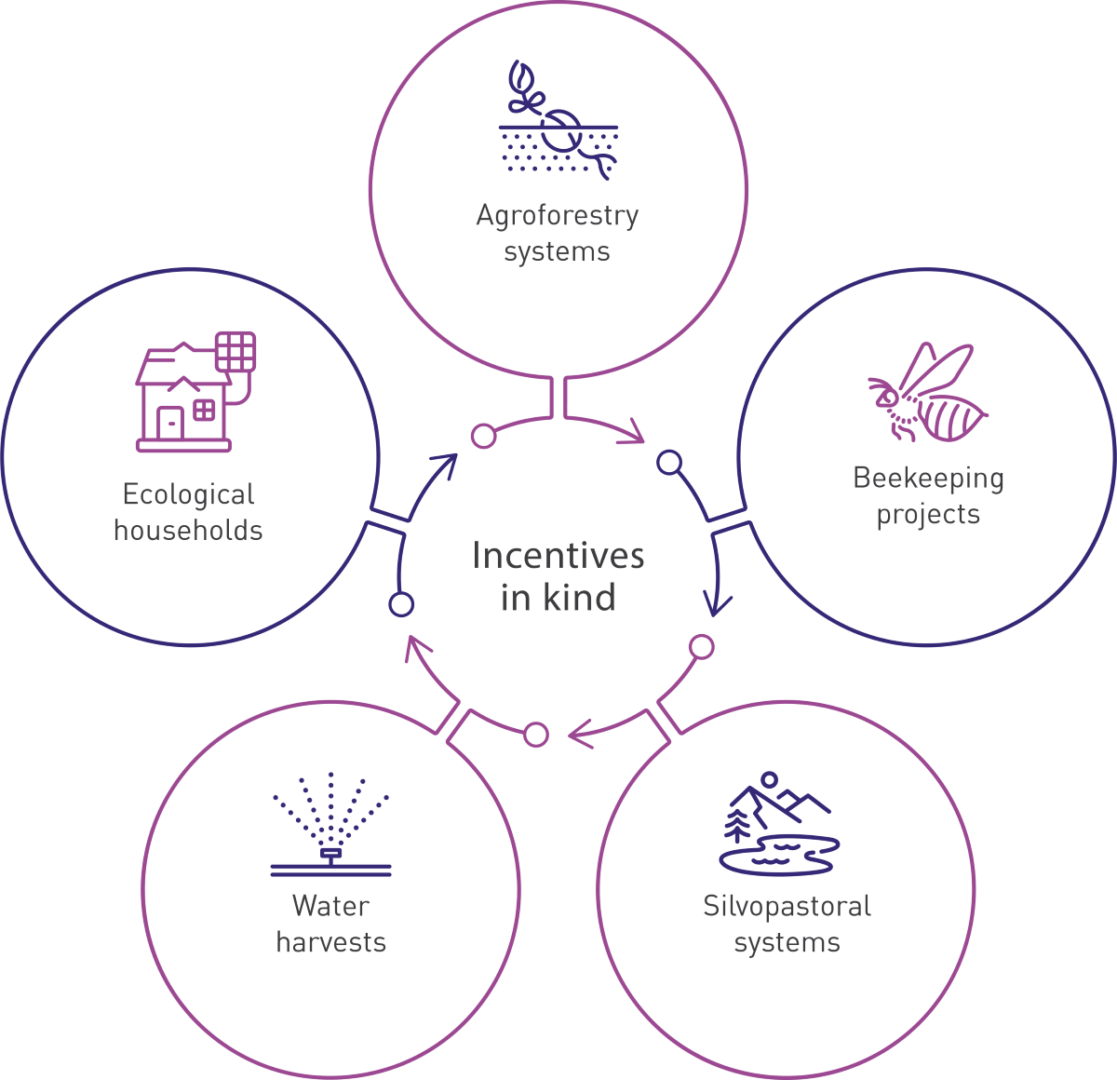

Ecopetrol S.A. elaborates investment and compensation plans for the conservation of biodiversity and its ecosystem services, in joint efforts with local communities in pre-established biodiversity clusters (Graph 28). These plans are implemented by signing voluntary conservation agreements, with incentives in kind, (Graph 29) to implement actions for the preservation, restoration, and/or sustainable use of biodiversity, in order to reduce conflicts between conservation and human activities.

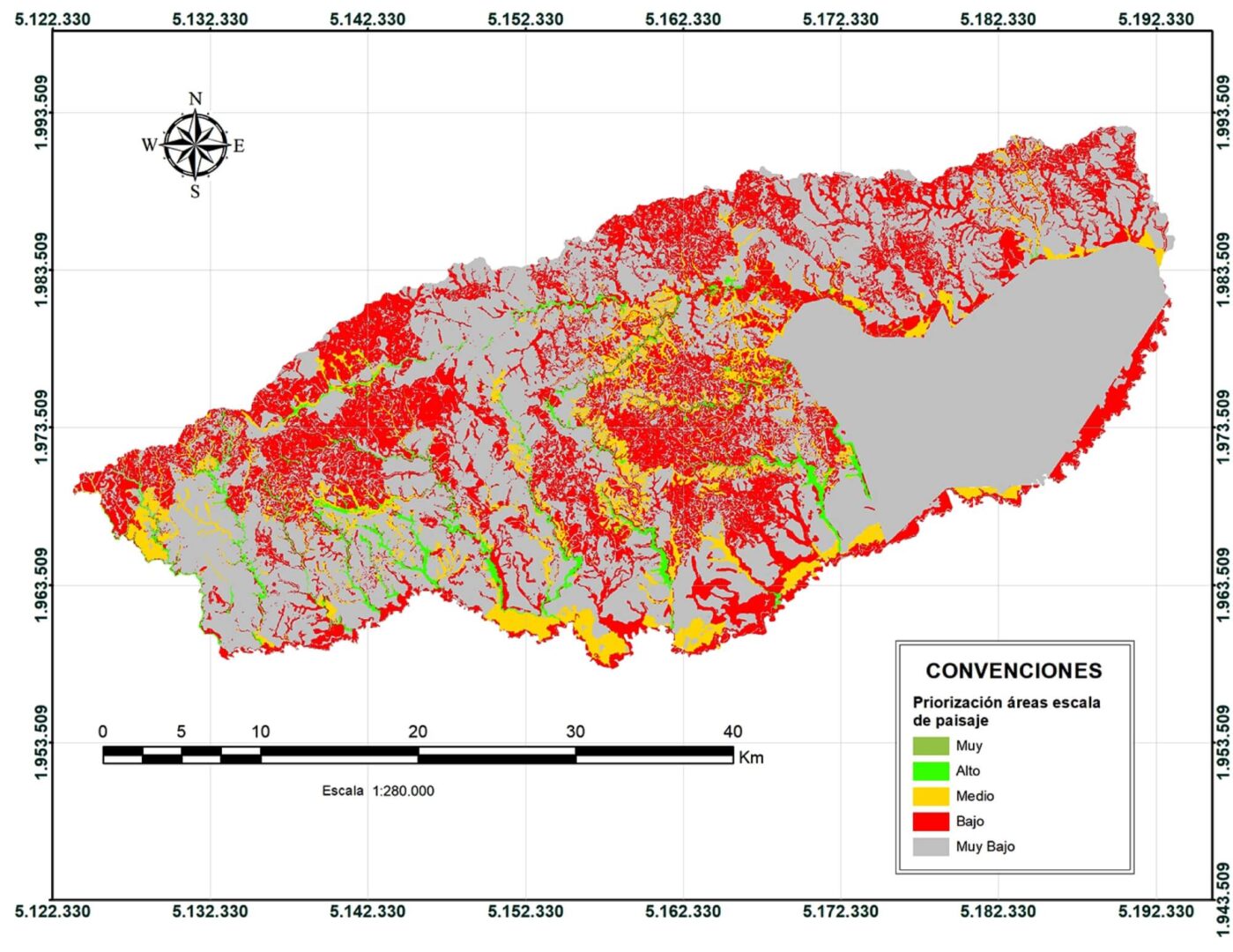

Biodiversity clusters Eastern Andean Region

Graph 28. Biodiversity clusters for the implementation of environmental compensation obligations and compulsory investments of not less than 1%, in the case of the Eastern Andean Regional Environmental Department. Top: Tillavá cluster; bottom: cluster landscapes.

Incentives in kind from voluntary conservation agreements

As of December 31, there

1,430 obligations reported

in Ecopetrol S.A.’s information system, of which 377 correspond to compulsory investment obligations of no less than 1% and 369 to compensation obligations required for forest exploitation permits by the regional environmental authorities.

(419-1) (307-1)

To learn about the fines and penalties incurred in the period for non-compliance with environmental or socioeconomic regulations, go to the GRI Index.

Roadmap

Climate Change

Exceptional

Material Element

Sustainable Development Goals

| Impacted stakeholder groups | Areas that manage the impacts | Ecopetrol segments that generate the greatest impact |

|---|---|---|

| Suppliers | VCU | Upstream |

| Associates and Partners | VAB | Mid-stream |

| Clients | HSE | Downstream |

| Employees | VDP | Commercial |

| Investors | VRP | |

| State | ||

| Society and Community |

Why is the element material?

The reality of climate change has led Ecopetrol to recognize Growing with the Energy Transition and Generating Value with TESG as pillars of the corporate strategy.

The effects of Climate Change have a direct and significant impact on the Company’s operations, infrastructure, and sustainability, and on all stakeholder groups. In accordance with the above, and as a result of the analysis conducted by Ecopetrol, this element was classified as exceptional.

How is the material

element managed?

Ecopetrol defined the “Climate Action” pillar (link) as part of the environmental strategy, which seeks to maintain low carbon emission operations, reduce the vulnerability of the infrastructure and operations to climate variability and change, as well as adequately manage risks and identify opportunities associated with climate change. This pillar includes four (4) subject areas:

1

Mitigation

2

Adaptation and vulnerability

3

Research, development, and innovation

4

Participation in the drafting of public policy documents

How is the material

element evaluated?

Short, medium, and long

term goals and projects

Short term (2022-2023

- Keep the GHG inventory updated and verified for Scopes 1, 2, and 3.

- Define the goal for reducing methane emissions and Scope 3 emissions

- by 2030

- Implement reduction projects (fugitive emissions and venting, flaring, renewable energy, and energy efficiency) and reduce 262,761 tCO2e

- in 2022

- Produce 400 MW of renewable energy for self-consumption in 2023

- Increase energy efficiency by 3% in 2023

- Prioritize and develop Natural Climate Solution (SNC, by its Spanish acronym) projects

Medium term (2024-2025)

- Verify the GHG inventory in 2025

- Reduce 1,600,000 tCO2e in the 2020-2024 period*.

- Research emerging technologies and conduct hydrogen and CCUS pilots

- Reduce Scope 3 emissions

- Progress in the SNC portfolio to meet 2030 compensation goals

Long term (>2025)

- Zero net emissions by 2050 and 25% reduction by 2030 (Scopes 1 and 2)

- 50% reduction of Scope 1, 2, and 3 emissions by 2050

- Zero Routine Flaring by 2030

- Increase energy efficiency by 6% between 2023-2028

- Gradual incorporation of projects associated with emerging technologies such as hydrogen and CCUS

- Capture two MtCO2e through CNS in 2030

Management Efforts

The following progress was achieved in 2021 towards meeting the goals outlined in the Roadmap:

(305-1) (305-2) (305-3) (WEF 7)

The 2017-2020 Emissions Inventory was verified by Ruby Canyon Engineering.

In 2021, the base year of the GHG inventory was updated to 2019. Ecopetrol’s GHG emissions inventory is prepared under the ISO 14064-1 methodology, and specifically, following the guidelines of the GHG Protocol Corporate Standard (Scope 1), the GHG Protocol Scope 2 Guidance (Scope 2), the Corporate Value Chain (Scope 3), and the Accounting and Reporting Standard (Scope 3).

The main methodologies used to estimate atmospheric emissions for Ecopetrol’s Scope 1 are mass balance and emission factors, although in some specific cases, engineering calculations or computer models are used. For Scopes 2 and 3, emission factors are used.

The information associated with GHG emissions, and their estimation is managed using the SAP-Environmental Compliance – SAPEC software solution.

The global warming potentials used in the inventory are the ones reported in the Fifth Assessment Report of the Intergovernmental Panel on Climate Change (IPCC-AR5).

The sources most often used in the inventory to obtain emission factors are the following:

- Compendium of Greenhouse Gas Emissions Estimation Methodologies for the Oil and Gas Industry

- FECOC

- UPME

- AP-42

- ARPEL

- CORINAIR

- Guideline for fugitive emission calculations, June 2003

Table 38.

Direct and indirect Scope 1, 2, and 3 GHG emissions

/table]

(305-1) (305-2) (305-3) (WEF 7)

| Emissions | Unit of measurement | 2018 | 2019 | 2020 | 2021 |

|---|---|---|---|---|---|

| Gross value of | |||||

| direct GHG emissions (Scope 1) | tCO2e | 11,193,834 | 11,141,393 | 10,238,780 | 10,296,909 |

| Gross value of indirect GHG emissions when generating energy (Scope 2) | tCO2e | 427,546 | 602,040 | 776,125 | 680,399 |

| Gross value of other indirect GHG emissions (Scope 3) | tCO2e | NA | 120,784,646 | 116,698,200 | 112,629,936 |

NOTE 1: i) Data adjusted based on SIGEA 2018, 2019, and 2020 updates, ii) The 2021 data corresponds to information inventoried for the first 10 months of 2021 and averaged for the months of November and December. These data will change once the final information is available.

NOTE 2: The gases included in the table are the following CO2, CH4 y N20.

NOTE 3: The first estimate of Scope 3 emissions made by the Company was for 2019.

With respect to the data presented in Table 38, it is important to note that Ecopetrol’s atmospheric emissions inventory is structured under the operational control approach, for upstream, midstream, and downstream activities. For the 2021 term, Cenit, a mid-stream subsidiary, left Ecopetrol’s operational control, which is why the historical series corresponding to the 2018-2020 is recalculated for this report.

In relation to the facility operation of Ecopetrol’s subsidiary, Oleoducto de Colombia (ODC), operational control was exerted by the Company until January 2021, at which time it was handed over to its subsidiary, Cenit. Consequently, the Ecopetrol inventory for the 2021 term includes the GHG emissions generated at the facilities of this subsidiary during this month.

Additionally, in 2020, Ecopetrol took over the operation of the upstream Pauto – Floreña asset, which is why the emissions of this asset are included in 2021 and the 2018-2020 historical series is recalculated.

In 2022, the GHG emissions of the subsidiaries operating in Colombia will continue being incorporated, which will imply reviewing the current reporting scope of the inventory.

Biogenic emissions

(305-1) (305-2) (305-3) (WEF 7)

| Emissions | Unit of measurement | 2018 | 2019 | 2020 | 2021 |

|---|---|---|---|---|---|

| Biogenic CO2 emissions Scope 1 | tCO2e | 981.59 | 265.68 | 331.28 | 478.09 |

| Biogenic CO2 emissions Scope 2 | tCO2e | ||||

| Biogenic CO2 emissions Scope 3 | tCO2e | 379,590 | 331,731 | 280,169 |

NOTE: i) Data adjusted based on SIGEA 2018, 2019, and 2020 updates, ii) The 2021 data correspond to information inventoried for the first 10 months of 2021 and averaged for the months of November and December. These data will change once the final information is available.

GHG emissions intensity

Upstream intensity is estimated using upstream emissions on the numerator, and the production of crude oil, gas, white products in BOE on the denominator, under the organizational limit of operational control.

The downstream intensity is estimated using Scope 1 and 2 refining and petrochemical emissions on the numerator, and the annual loads to the Barrancabermeja and Cartagena refineries in the BOE on the denominator.

The gases included in the following table are CO2, CH4, and N2O.

GHG emissions intensity

| Process | Unit of measurement | 2018 | 2019 | 2020 | 2021 |

|---|---|---|---|---|---|

| Production | KgCO2e/BOE | 25.7 | 26.7 | 28.8 | 29.6 |

| Refining and petrochemicals | KgCO2e/BOE | 44.2 | 42.8 | 42.4 | 39.9 |

NOTE: i) Data adjusted based on SIGEA 2018, 2019, and 2020 updates, ii) The 2021 data correspond to information inventoried for the first 10 months of 2021 and averaged for the months of November and December. These data will change once the final information is available.

The reduced carbon intensity of the refining segment between 2020 and 2021 is mainly due to the implementation of energy efficiency actions at the refineries and reduced venting emissions at the Cartagena Refinery.

The increase in carbon intensity in the production segment is mainly due to the reversal of assets with a higher level of carbon intensity, previously operated by a third party (Pauto and Floreña), and higher energy consumption associated with the types of crude oil that are part of the company’s portfolio.

Reduction of

GHG emissions

293,594 tCO2e

were reduced in 2021 thanks to the implementation of new projects, far exceeding established goal of 235,262 tCO2e

by 25%

The emission reduction projects implemented are quantified using mass balance and emission factors.

The emission factors of the instruments below were used for calculation:

- Compendium of Greenhouse Gas Emissions Estimation Methodologies for the Oil and Gas Industry

- FECOC

- UPME

- AP-42

Projects implemented to reduce or avoid emissions

| Description of the initiative | Gases included in the calculation | Scopes that led to reductions | Standards or methodologies used for calculation | Development stage |

|---|---|---|---|---|

| Energy efficiency: Includes projects associated with changes in the energy matrix for another of less impact and process optimization. 42 projects were executed in the 2018- 2021 period (1 in 2018, 3 in 2019, 14 in 2020, and 24 in 2021). | CO2 CH4 N2O | Scope 1 | Estimated reductions using mass balance and/or emission factors in Ecopetrol’s own calculation model. | Implemented |

| Fugitive emissions and vents: includes projects associated with the elimination of leaks and vents in the processes. 15 projects were executed in the 2018-2021 period (1 in 2018, 6 in 2020, and 8 in2021). | CH4 | Scope 1 | Estimated reductions using mass balance and/or emission factors in Ecopetrol’s own calculation model. | Implemented |

| Optimization of flaring: includes projects associated with the optimization of flaring through the sale, self- generation, or optimization of the process. 19 projects were executed in the 2018- 2021 period (2 in 2018, 2 in 2019, 6 in 2020, and 9 in 2021). | CO2 CH4 | Scope 1 | Estimated reductions using mass balance and/or emission factors in Ecopetrol’s own calculation model. | Implemented |

| Renewable energy: includes projects associated with energy generation via renewable sources. Three projects were implemented in the 2018-2021 period (1 in 2019 and 2 in 2021). | CO2 | Scope 2 | Estimated reductions using mass balance and/or emission factors in Ecopetrol’s own calculation model. | Implemented |

[/src]

Tons of GHG emissions reduced or avoided as a direct consequence of reduction initiatives in each of the projects

| Emissions | Unit of measurement | 2018 | 2019 | 2020 | 2021 |

|---|---|---|---|---|---|

| Energy efficiency | tCO2e | 35,990 | 161,473 | 128,596 | 186,713 |

| Fugitive emissions and vents | tCO2e | 33,894 | 0 | 23,257 | 59,817 |

| Optimization of flaring | tCO2e | 35,386 | 210,370 | 47,994 | 45,135 |

| Renewable energies | tCO2e | 0 | 8,760 | 0 | 1,929 |

NOTE: i) Data adjusted based on SIGEA 2018, 2019, and 2020 updates,

ii) The 2021 data correspond to information inventoried for the first 10 months of 2021 and averaged for the months of November and December. These data may change once the final information is available.

Progress was made in 2021 in the detection and measurement of methane emissions, which reached

95%

at the production facilities of Ecopetrol operated assets, using a bottom-up approach (based on representative samples using infrared cameras and others).

By adopting a top-down approach (measurement at a regional scale using satellite images or overflights), Ecopetrol covered 95% of the production facilities, the Barrancabermeja and Cartagena refineries, the Unconventional Reservoirs (YNC) pilot project, and the assets with partners in Middle Magdalena using an aircraft with specific methane sensors and

covering a total of

1,205 Km2.

Management strategy

for fugitive emissions,

venting, and burning

Ecopetrol has a fugitive emissions and venting management strategy, which seeks the following:

- Achieve compliance with the sectoral goal of reducing methane emissions from member companies of the Climate and Clean Air Coalition (CCAC) by 2025 in absolute terms of

45%

between

60% and 75%

by 2030, exceeding the levels estimated for 2015. In 2022, Ecopetrol will establish its own methane emission reduction goal.

- Report a maximum of

100% of operated assets in 2024 and

100% of non-operated

assets in 2026, at the

4/5 measurement level

in accordance with the commitments established for OGMP 2.0 members. (Oil and Gas Methane Partnership).

To this end, progress is being made in the development and implementation of the following lines of action:

(i)

Updating and adjusting the methane emissions inventory, construction of own emission factors, and definition of reduction goals.

(ii)

Incorporation of design criteria and good engineering practices to reduce fugitive emissions and venting.

(iii)

Implementation of the LDAR – Leak Detection and Repair, a program for the identification, quantification, and repair of methane emission leaks.

With respect to the reduction of flaring, Ecopetrol aims to eliminate its routine burning by 2030, in line with the World Bank’s “Zero Routine Flaring by 2030” initiative, in order to reduce routine burning in existing fields and avoid routine burning in new oil reservoirs.

A new campaign to detect methane emissions was deployed in 2021, with greater coverage than the campaign conducted between 2019 and 2020, identifying

1,085 leaks

that already have an action plan, and of which,

184 (17%)

have already been closed

Public Policy efforts

related to climate change

Ecopetrol articulates its climate change strategy with the National Government’s public policy and contributes to the construction of technical and regulatory guidelines to strengthen the country’s institutional capacity in the area of climate change.

In 2021, Ecopetrol participated in working groups to draft the following documents, regulations, and strategies associated with climate change:

(i)

Colombia’s Long-Term Climate Strategy E2050,

(ii)

Update to the Comprehensive Climate Change Management Plan for the Mines and Energy sector,

(iii)

The Climate Action Law,

(iv)

Conpes “Public policy to reduce disaster risk conditions and adapt to climate variability phenomena”,

(v)

The Energy Transition Law and the promotion of Non-conventional sources of energy,

(vi)

Colombia’s The Hydrogen Roadmap, and

(vii)

The proposed resolution for the regulation of fugitive emissions, vents, and flaring.

Furthermore, the Company joined the Carbon Neutrality Program led by the Ministry of Environment and Sustainable Development of Colombia and signed a Voluntary Agreement with the MME to promote carbon neutrality and climate resilience in the hydrocarbon sector.

In terms of global initiatives, the Company is part of the Climate and Clean Air Coalition (CCAC) led by the United Nations, the International Petroleum Industry Environmental Conservation Association (IPIECA), and Zero Routine Flaring by 2030 led by the World Bank.

Roadmap

Integrated Water Management

Exceptional

material element

Sustainable Development Goals

| Impacted stakeholder groups | Areas responsible for managing the impacts | Ecopetrol segments with the greatest impact |

|---|---|---|

| Society and Community | VDS | Upstream |

| Investors and Shareholders | VSHE | Downstream |

| Local State | VDP | |

| Employees | VRP | |

| National State | ||

| Clients | ||

| Suppliers |

Why is the element material?

Integrated Water Management is an Exceptional element of the Generating Value with TESG pillar of the Corporate Strategy. This is due to its significant impact on value generation in the short, medium, and long term, and its relevance for stakeholders.

Responsible management of water resources is essential for the operational continuity of the different business areas, as well as to ensure the protection and conservation of the ecosystem service and its availability for communities and society.

¿How is the material

element managed?

The Integrated Water Management Roadmap was defined in 2021, targeting water neutrality by 2045 on the path toward positive net water. This means replacing 100% of the water consumed by the operations, thereby generating a positive impact in the basins used as catchments or discharges. To achieve this goal, Ecopetrol focuses on the following:

Improving operational efficiency in water management (leveraging on the implementation of technology and the generation of knowledge), reducing freshwater catchments and discharges by maximizing internal reutilization and the use of alternative water sources (e.g., municipal wastewater, seawater, brackish water from deep aquifers, etc.), and the reutilization of produced water in other sectors (e.g., agriculture).

Protection of water basins by implementing own and collective actions that compensate the remaining volume of water consumed by the operations.

How is the material

element evaluated?

Integrated water management is evaluated using the three (3) indicators below, which are monitored on a monthly basis.

Reduction of the volume of fresh water withdrawn for industrial use

Percentage of reutilization of collected water and produced water to leverage the reduction of catchments and discharges

Volume of water reused in other sectors (e.g., agriculture).

In 2021, the water reutilization indicator was incorporated into Ecopetrol S.A.’s TBG, which is part of the variable remuneration, and this goal was exceeded as a result.

These goals are updated annually under the principle of continuous improvement, and they are monitored based on information uploaded by the Group’s businesses in the SIGAR-Aguas tool. The results of the indicators are presented monthly to the HSE and management committees of the Vice Presidency of Production and the Vice Presidency of Refining and Petrochemicals.

In 2021, the water reutilization indicator was incorporated into the Ecopetrol Group’s TBG, which is part of the variable remuneration.

Short-term goals are updated annually.

Short, medium,

and long-term

goals and projects

The Integrated Water Management Roadmap towards Water Neutrality sets goals to optimize water use, maximize reutilization, increase reutilization, and reduce water catchments and discharges.

All the goals presented below were established with respect to 2019 (base year) and are outlined for compliance with the objective of water neutrality:

- Reduce 14% of freshwater catchment

- Increase the reutilization of produced water to 28.8%

- Maintain industrial water reutilization at 41.2%

Medium term (2030)

- Reduce 58% of freshwater catchment for industrial use

- Reduce 66% of industrial discharges to surface water bodies

Medium term (2030)

- Reduce 66% of freshwater catchment for industrial use

- Reduce 100% of industrial discharges to surface water bodies

2021 Management Efforts26

The main achievements of the efforts towards water neutrality with respect to the base year (2019) were:

Interaction with water

as a shared resource

(103-1) (WEF 11E)

Superficial (61% of total water catchment): 29% reduction compared to 2020 due to lower water catchment requirements for recovery in the La Cira Infantas (-1.2 million m3) and Yaguará (-31 thousand m3) fields. It is important to note that the volume of drinking water delivered to the community of El Centro (approximately 8.8 million m3) is not included as of 2021.

Underground (21% of total water catchment): 6% reduction compared to 2020, mainly due to lower water requirements for recovery in Tibú (-941 thousand m3 due to public order conditions) and Yariguí-Cantagallo (-331 thousand m3 due to optimizations in the recovery process).

Aqueducts and external suppliers (18% of total water catchment): 4% reduction compared to 2020 due to lower catchments at the Cartagena Refinery.

Marine waters (0.0%): 0.01 million m3 of marine waters to test fire-fighting systems.

The water collected is mainly used for refining processes (71.0%), followed by Production (28.8%), and the remaining 0.2% was used in administrative areas.

Impact identification and

management due to catchments

(103-1) (WEF 11E)

Water consumption by Ecopetrol assets ranges between

0 and 2.5%

of the water supply of the basins where catchment takes place, which is why the potential impact of the activities is not significant.

That said, the impacts that Ecopetrol can generate on water are related to water consumption, which, under natural circumstances of scarcity due to climatic variability and seasonal rainfall, could generate changes in water availability for users in the catchment points downstream. To reduce this potential impact, Ecopetrol, during the environmental planning phase of each project or initiative, and in accordance with the methodology established by the ANLA, identifies the availability dynamics of water resources in the area of influence, and defines catchment limits and management and monitoring measures to be incorporated in the environmental management plans subject to evaluation and approval by the Environmental Authority.

Ecopetrol files a licensing and permitting process with the environmental authorities before using or exploiting the water resources. The licenses and permits granted set the conditions so that catchments and discharges do not generate significant impacts on the availability and quality of water bodies. Once the authorizations have been granted, legal compliance therewith is supervised, and the supply and quality conditions of the water bodies are continuously monitored. The monitoring results are recorded in the SIGAR – Aguas tool to identify potential deviations and generate the corresponding corrective action plans.

At the operational and corporate level, operational efficiency strategies are planned and implemented in water management in order to reduce the Company’s freshwater catchment and discharge volumes, accompanied by a technological component and the protection of natural capital in the basins.

Lastly, Ecopetrol uses the water footprint calculation methodology (ISO 14046:2014) to assess the following:

The consumption footprint

Extracted fresh water that evaporates, is incorporated into the product, or that is not returned to the basin

The water scarcity footprint

Impact of water consumption with respect to available fresh water

The degradation footprint

Deterioration of freshwater quality due to the presence of polluting substances

Sustainability

and Water Security

For Ecopetrol, it is essential to support and be associated with water security efforts at the international and national levels, which is why it participates in the CEO Water Mandate and Water Coalition for Colombia initiatives. Currently, the water security initiatives promoted by Ecopetrol are part of the Water Action Hub, the global collaboration and knowledge exchange platform for water sustainability and climate resilience.

At the regional level, and as part of the formulation of a Water Governance Mechanism for the supply basins in the municipalities of Acacías and Villavicencio, the Promoter Group was created in 2021, together with The Nature Conservancy (TNC), with the participation of

16 public and private entities

interested in collective action, to solve the water security challenges of said basins in the department of the Meta. This initiative contributes to the purpose of offsetting the remaining consumption footprint to achieve the goal of water neutrality.

In partnership with IDEAM, Ecopetrol updates and monitors the status of surface water resources and generating hydrometeorological alerts in the VMM. Moreover, to improve knowledge of the basins in the area of influence associated with Ecopetrol operations, a water security situational analysis was conducted in the hydrographic subzones of the Opón and Sogamoso rivers and the middle and lower basins of the Lebrija river in the department of Santander.

Lastly, Ecopetrol continues deploying actions for the conservation of natural capital and biodiversity, through voluntary efforts and by complying with the obligations of environmental compensation and

1%,

investment, which contribute to the conservation and monitoring of water resources.

Management of impacts

related to water discharges

(103-2) (WEF 11E)

With respect to discharges, a total of 61.6 million m³ were recorded,

41% less than in 2020,

mainly due to

(i)

The closure of 90,000 barrels of water to the Magdalena River and

(ii)

the interruption of the Castilla field discharge in the first half of the year.

94.4% of the total was discharged into surface water bodies, 4.1% into the sea, 1.2% into the ground, and 0.2% into external managers and sewers. Exploration and production activities generated

76.7% of total discharges

(mainly production), Refining 23.2%, and corporate areas 0.1%.

Identification and management

of impacts due to discharges

(303-1) (WEF 11E)

The discharges could change the quality of the water bodies. In this case, environmental evaluations are conducted from the planning stage, based on the load and the assimilation and dilution capacity of the receiving body to confirm that no significant impacts are generated on them. Ecopetrol treats

100% of its wastewater

before being discharged and ensures compliance with the maximum permissible values established in national and local environmental regulations. In addition, the Company monitors the receiving bodies to confirm that they are not affected by their discharges.

Discharge quality criteria are established by competent environmental authorities, who determine the maximum permissible values for discharges to surface water bodies and sewers, seawater, and soil, applicable to each productive sector of the industry. Specifically for the hydrocarbon sector, maximum values are defined depending on the activity within the value chain (Exploration, Production, Refining, and Transportation), and the Company monitors more than 40 quality-related parameters.

To define the quality criteria, in compliance with current regulations, Ecopetrol conducts environmental assessments of the discharges based on the assimilation and dilution capacity of the receiving bodies to minimize impacts on the resource.

Priority Substances

Ecopetrol uses the results of the water footprint evaluation (ISO 14046) to define the priority substances in discharge management. To this end, the following water degradation impact indicators are included in the assessment:

(i)

Human toxicity: based on the USEtox model, it assesses the danger of wastewater discharges in terms of carcinogenic and non-carcinogenic toxicity for humans (CTUh).

(ii)

Ecotoxicity in fresh water: based on the USEtox model, it evaluates various toxicological mechanisms caused by the release of substances with a direct effect on the health of the ecosystem in (CTUe).

(iii)

Ecotoxicity of seawater: based on the Recipe model.

(iv)

Fresh water acidification: based on the Accumulated Excess EA model, it evaluates the impact on fresh water due to the release of NOx, SOx, and NH3 into the atmosphere, which could cause acid rain. In addition, environmental regulations define the most relevant parameters for each productive sector and establish the corresponding maximum allowable limits.

Water extraction by area

(303-3) (WEF 10)

| Water extraction by area | Unit of measurement | 2018 | 2019 | 2020 | 2021 |

|---|---|---|---|---|---|

| Total extraction all areas | Thousands of m3 | 440,089 | 453,769 | 454,658 | 428,243 |

| Total surface water | Thousands of m3 | 38,569 | 38,369 | 34,465 | 24,326 |

| Surface: Fresh water (total dissolved solids ≤1000mg/l) | Thousands of m3 | 38,569 | 38,369 | 34,465 | 24,326 |

| Surface: Other waters (total dissolved solids >1000mg/l) | Thousands of m3 | – | – | – | – |

| Total groundwater | Thousands of m3 | 10,800 | 8,459 | 9,347 | 8,771 |

| Underground: Fresh water (total dissolved solids ≤1000mg/l) | Thousands of m3 | 10,800 | 8,459 | 9,347 | 8,771 |

| Underground: Other waters (total dissolved solids >1000mg/l) | Thousands of m3 | – | – | – | – |

| Total sea water | Thousands of m3 | – | – | – | 10 |

| Sea: Fresh water (total dissolved solids ≤1000mg/l) | Thousands of m3 | – | – | – | – |

| Sea: Other waters (total dissolved solids >1000mg/l) | Thousands of m3 | – | – | – | 10 |

| Total aqueducts | Thousands of m3 | 8,154 | 7,800 | 7,301 | 6,983 |

| Aqueducts: Fresh water (total dissolved solids ≤1000mg/l) | Thousands of m3 | 8,154 | 7,800 | 7,301 | 6,983 |

| Aqueducts: Other waters (total dissolved solids >1000mg/l) | Thousands of m3 | – | – | – | – |

| Total produced water | Thousands of m3 | 382,567 | 399,141 | 403,544 | 388,152 |

| Total produced water: Fresh water (total dissolved solids ≤1000mg/l) | Thousands of m3 | 84,574 | 91,618 | 100,150 | 302,003 |

| Total produced water: Other waters (total dissolved solids >1000mg/l) | Thousands of m3 | 297,993 | 307,523 | 303,394 | 86,149 |

Note: There is a significant difference between “fresh water” and “other waters in the produced water category, given that in 2021, the monitors of the Rubiales field (approximately 220 million m3) showed TDS values less than 1,000 ppm (fresh water), while in 2020, they had been above 1,000 ppm (other waters).

Water extraction by water stressed areas

| Water extraction by water stressed area | Unit of measurement | 2018 | 2019 | 2020 | 2021 |

|---|---|---|---|---|---|

| Total extraction water stressed areas | Thousands of m3 | 25,877 | 25,202 | 23,456 | 24,647 |

| Total surface water | Thousands of m3 | 4,598 | 4,067 | 3,231 | 4,005 |

| Surface: Fresh water (total dissolved solids ≤1000mg/l) | Thousands of m3 | 4,598 | 4,067 | 3,231 | 4,005 |

| Surface: Other waters (total dissolved solids >1000mg/l) | Thousands of m3 | – | – | – | – |

| Total groundwater | Thousands of m3 | 313 | 248 | 69 | 84 |

| Underground: Fresh water (total dissolved solids ≤1000mg/l) | Thousands of m3 | 313 | 248 | 69 | 84 |

| Underground: Other waters (total dissolved solids >1000mg/l) | Thousands of m3 | – | – | – | – |

| Total sea water | Thousands of m3 | – | – | – | 10 |

| Sea: Fresh water (total dissolved solids ≤1000mg/l) | Thousands of m3 | – | – | – | – |

| Sea: Other waters (total dissolved solids >1000mg/l) | Thousands of m3 | – | – | – | 10 |

| Total aqueducts | Thousands m3 | 8,078 | 7,740 | 7,220 | 6,970 |

| Aqueducts: Fresh water (total dissolved solids ≤1000mg/l) | Thousands of m3 | 8,078 | 7,740 | 7,220 | 6,970 |

| Aqueducts: Other waters (total dissolved solids >1000mg/l) | Thousands of m3 | – | – | – | – |

| Total produced water | Thousands of m3 | 12,887 | 13,146 | 12,935 | 13,578 |

| Total produced water: Fresh water (total dissolved solids ≤1000mg/l) | Thousands of m3 | – | – | – | – |

| Total produced water: Other waters (total dissolved solids >1000mg/l) | Thousands of m3 | 12,887 | 13,146 | 12,935 | 13,578 |

Notes

- There is evidence of a 20% increase compared to 2020 in the extraction of surface fresh water in water stressed areas (water use index greater than 40%), mainly due to increased catchment by the Barrancabermeja Refinery in the San Silvestre swamp (+822 thousand m3).

- With regard to groundwater, there was a 21% increase due to higher catchments for industrial use in the Dina Cretáceos, Lisama, and San Francisco fields.

- Total water extraction in water stressed areas is equivalent to 6% of Ecopetrol’s total extraction.

Amount of water reused by Ecopetrol in 2021

(OG-5) (WEF 10)

| Water reutilization | Unit of measurement | 2018 | 2019 | 2020 | 2021 |

|---|---|---|---|---|---|

| Total water reutilization | Thousands of m3 | 85,015 | 89,396 | 96,524 | 111,262 |

| Water catchment reutilization | Thousands of m3 | 17,660 | 16,971 | 11,365 | 16,873 |

| Produced water reutilization | Thousands of m3 | 67,355 | 72,424 | 85,159 | 94,389 |

Note: There was a 15% increase in the total volume of reused water due to:

- Increased reutilization of water catchment at the Barrancabermeja Refinery (+4.9 million m3) after identifying reutilization currents that had not been reported, as well as increased reutilization at the Cartagena Refinery (+683 thousand m3)

- Increased reutilization of produced water due to better performance in injection for recovery, Castilla +5.4 million m3, Apiay and Suria +343 thousand m3, Chichimene +2.7 million m3.

- A total of 94.4 million m3 of production water were reused, which means a percentage of reuse of 24% with respect to the total water produced, achieving 106% compliance with the goal established for 2021 (22.4 %).

- A total of 16.9 million m3 of effluents from the use of collected water were reused/recirculated, which represents a reuse of 42% with respect to the volume collected, achieving 133% compliance with the goal established for 2021 (34, two%).

Effluent management

| Effluent management | Unit of measurement | 2018 | 2019 | 2020 | 2021 |

|---|---|---|---|---|---|

| Reutilization | Thousands of m3 | 85,015 | 89,396 | 96,524 | 111,262 |

| Reutilization | Thousands of m3 | 52 | 1,159 | 3,134 | 2,305 |

| Disposal | Thousands of m3 | 243,975 | 249,339 | 245,429 | 246,940 |

| Discharges | Thousands of m3 | 100,011 | 96,686 | 87,278 | 61,555 |

| Total effluents | Thousands of m3 | 429,053 | 436,580 | 432,365 | 422,061 |

Amount of water discharge in all areas

| Water discharge in all areas | Unit of measurement | 2018 | 2019 | 2020 | 2021 |

|---|---|---|---|---|---|

| Surface water | Thousands of m3 | 97,050 | 93,035 | 83,942 | 58,199 |

| Sea water | Thousands of m3 | 2,061 | 2,671 | 2,360 | 2,508 |

| Soil water | Thousands of m3 | 816 | 850 | 849 | 751 |

| Sewage water | Thousands of m3 | 84 | 131 | 128 | 97 |

| Total discharges by fresh water (total dissolved solids ≤1000mg/l) | Thousands of m3 | 66,192 | 65,703 | 56,872 | 45,832 |

| Total discharges by other waters (total dissolved solids >1000mg/l) | Thousands of m3 | 33,819 | 30,983 | 30,407 | 15,723 |

[/src]

Note: There was a 29% reduction of total discharges by the Company, mainly due to the temporary suspension of the discharge from Castilla. With regard to the differentiation of discharges by their TDS content, there was a 19% reduction in the “freshwater line <1000 ppm TDS” due to the suspension of the discharge from Castilla (-23.5 million m3), and the inclusion in 2021 (according to legal monitoring) as fresh water from the discharges of Rubiales (+12.8 million m3).

Amount of water discharge by water stressed areas

| Water discharge in water stressed areas | Unit of measurement | 2018 | 2019 | 2020 | 2021 |

|---|---|---|---|---|---|

| Surface water | Thousands of m3 | 564 | 532 | 480 | 584 |

| Sea water | Thousands of m3 | 2,059 | 2,669 | 2,339 | 2,508 |

| Soil water | Thousands of m3 | 213 | 276 | 140 | 107 |

| Sewage water | Thousands of m3 | 34 | 61 | 19 | – |

| Total discharges by fresh water (total dissolved solids ≤1000mg/l) | Thousands of m3 | 335 | 464 | 257 | 180 |

| Total discharges by other waters (total dissolved solids >1000mg/l) | Thousands of m3 | 2,535 | 3,075 | 2,721 | 3,019 |

Note: The increased volume of discharges in water stressed areas is due to higher discharges in Llanito (+104 thousand m3) and the Cartagena Refinery (+170 thousand m3). The discharge from Llanito was definitively eliminated as of November 2021.

Amount of discharge by treatment level

| Discharge by treatment level | Unit of measurement | 2018 | 2019 | 2020 | 2021 |

|---|---|---|---|---|---|

| Without treatment | Thousands of m3 | – | – | – | – |

| Pretreatment | Thousands of m3 | – | – | – | – |

| Primary treatment | Thousands of m3 | 17,091 | 9,476 | 3,844 | 4,302 |

| Secondary treatment | Thousands of m3 | 82,835 | 87,081 | 83,319 | 57,197 |

| Tertiary treatment | Thousands of m3 | 3 | 2 | 0 | – |

| Other treatments | Thousands of m3 | 82 | 127 | 115 | 56 |

Note: In primary treatments, discharges with exclusively physical treatments are reported; secondary treatments involve biological treatments; tertiary treatments include advanced treatments like reverse osmosis. The volume reported under “Other treatments” corresponds to wastewater delivered to external managers, who are responsible for the final treatment and disposal. The decrease in water discharged with tertiary treatments is because these streams were 100% reused.

No events exceeding maximum permissible discharge parameters were recorded in 2021.

Ecopetrol’s 2021 water consumption in water stressed areas

| Water consumption | Unit of measurement | 2018 | 2019 | 2020 | 2021 |

|---|---|---|---|---|---|

| Inlets | Thousands of m3 | 25,877 | 25,202 | 23,456 | 24,647 |

| Fresh water catchments | Thousands of m3 | 12,989 | 12,055 | 10,520 | 11,069 |

| Produced water | Thousands of m3 | 12,887 | 13,146 | 12,935 | 13,578 |

| Effluents | Thousands of m3 | 15,490 | 16,558 | 15,486 | 16,179 |

| Water catchment injected for recovery | Thousands of m3 | 250 | 234 | 41 | 0.08 |

| Drinking water supplied to third parties (communities) | Thousands of m3 | 71 | 95 | 4 | – |

| Produced water reinjected for recovery | Thousands of m3 | 12,299 | 12,691 | 12,462 | – |

| Produced water reinjected for final disposal | Thousands of m3 | – | – | – | – |

| Reutilization of produced water for agricultural irrigation | Thousands of m3 | – | – | – | – |

| Discharges | Thousands of m3 | 2,870 | 3,539 | 2,978 | 3,199 |

| Balance (consumption) | Thousands of m3 | 10,387 | 8,643 | 7,970 | 8,469 |

Amount of water produced by produced water management method in 2021

(G-5) (WEF WEF 10)

| Produced water by disposal method | Unit of measurement | 2018 | 2019 | 2020 | 2021 |

|---|---|---|---|---|---|

| Total water produced | Thousands of m3 | 383,270 | 399,164 | 405,770 | 389,397 |

| Discharge | Thousands of m3 | 71,888 | 76,241 | 72,047 | 45,763 |

| Reinjected as final disposal | Thousands of m3 | 243,975 | 249,339 | 245,429 | 246,940 |

| Reinjected for recovery | Thousands of m3 | 67,146 | 71,685 | 84,845 | 94,259 |

| Reused | Thousands of m3 | 52 | 1,159 | 3,134 | 2,305 |

| Other reuses | Thousands of m3 | 209 | 739 | 314 | 130 |

Roadmap

Biodiversity

Outstanding

Material Element

Sustainable Development Goals

| Impacted stakeholder groups | Areas responsible for managing the impacts | Ecopetrol segments with the greatest impact |

|---|---|---|

| Suppliers, contractors, and their workers | VHSE | Upstream |

| Clients | Midstream | |

| Investors and Shareholders | Downstream | |

| National State | ||

| Local State | ||

| Society and Communities | ||

| Associates and Partners | ||

| Employees, Pensioners, and their Beneficiaries |

Why is the

element material?

Ecopetrol defined Biodiversity and Ecosystem Services as an outstanding element, considering the risks and opportunities it represents for the Company in a mega-diverse country. This is also in order to properly manage biodiversity and ecosystem services, meeting the expectations of stakeholders and retaining the license to operate.

Ecopetrol recognizes the need to identify and manage the dependencies and potential impacts on biodiversity and ecosystem services, as well as the importance of adopting actions for conservation, in line with the SDGs.

How is the material

element managed?

This material element is managed in compliance with four (4) subject areas that are part of the Generating Value with TESG pillar of the 2040 Strategy, which places particular emphasis on generating value in the energy transition and the decarbonization of operations.

The four (4) subject areas are:

Mitigation Hierarchy:

its purpose is to prevent, avoid, mitigate, and offset potential residual impacts.

Nature-based solutions:

the network of eco-reserves and natural climate solution and tree planting projects seek to respond to challenges associated with climate change, water resource management, biodiversity and ecosystem services, together with local communities.

Knowledge generation:

this includes the generation of information on biodiversity and ecosystem services to strengthen decision-making.

Culture of biodiversity:

this seeks to strengthen the value of biodiversity and ecosystems in the Company.

The Company’s aspirations and goals in terms of biodiversity are reflected in the Biodiversity Strategy, which is based on the following guiding principles:

Prevention

Caution

No net loss

Positive net impact

To implement the Biodiversity Strategy, Ecopetrol established partnerships with national and international environmental entities such as the Ministry of Environment and Sustainable Development of Colombia, the Alexander von Humboldt Institute, Wildlife Conservation Society (WCS), Fondo Acción, TNC, Fundación Natura, South Pole, and ISA (Conexión Jaguar).

How is the material

element evaluated?

Like all the material elements of the Company, Biodiversity and Ecosystem Services has its Roadmap with goals, management indicators, and milestones to be achieved in the short, medium, and long term. Depending on their relevance, some are included in the TBG.

In terms of mandatory investments, specific indicators are defined as part of the compensation plans approved by the respective environmental authority, such as

- Hectares under conservation

- Trees planted

- Connectivity

- Deforestation avoided

- Presence of species

Indicators are also defined for voluntary initiatives, such as hectares under conservation, trees planted, and carbon captured, which are previously agreed on with the different allies undertaking these initiatives (e.g., TNC, WCS, Fundación Natura).

With regard to potential impacts, the main indicators monitored include hectares intervened, volume of forest exploitation, effect on species on the IUCN Red List, and spills affecting flora and fauna.

Ecoreserves are geographically delimited areas on Ecopetrol Group’s property that are voluntarily allocated, either partially or completely, to the conservation (preservation, restoration, sustainable use, or knowledge) of biodiversity and the supply of ecosystem services, without limiting their productive and exploratory vocation. They are also part of the set of Nature-Based Solutions (SBN, by its Spanish acronym) and generally offer opportunities with multiple benefits to face challenges related to climate change, risk and disaster reduction, improvements in water security, food security, human health, and socioeconomic development, among others, on the path towards a net positive impact on biodiversity.

Short, medium,

and long-term

goals and projects

27. These 30,000 hectares correspond to the effectively restored/conserved area. Considering the area of influence of the different projects with ISA – Conexión Jaguar, WCS, Fondo Acción, Fundación Natura, The nature Conservancy, Cormacarena and Gobernación del Meta, this figure amounts to approximately 1.84 million ha.

Ecopetrol is committed to achieving Net Zero Deforestation and Net Positive Impact in its own operations and in the supply chain, for this reason it evaluates the commitments that will be defined in 2022, its scope and implications.

(304-2) (WEF 9)

Hydrocarbon activity in Colombia takes place under an environmental zoning process that applies the mitigation hierarchy, thus avoiding, minimizing, and correcting impacts on biodiversity and only offsetting residual impacts.

The main impacts on biodiversity derive from the following actions related to Ecopetrol’s operations:

- The construction or use of manufacturing plants, mines, and transportation infrastructure

- Pollution (introduction of non-naturally occurring substances into a habitat from both point and non-point sources)

- The transformation of the habitat

- Land use change

- Habitat transformation

- Pollution

In 2021, a total of

52.16 ha

were intervened, with

407.08 m3 of wood,

extracted mostly from isolated trees.

The most affected species were flora species and all interventions undertaken are reversible.

These are also subject to environmental compensation via the implementation of conservation or restoration projects by deploying the actions, modes, mechanisms, quantities, and formats enabled in each environmental management instrument.

In order to minimize these impacts, the company conducts biodiversity management processes and ecosystem services to generate the least amount and magnitude of residual impacts, based on the implementation of the mitigation hierarchy.

In compliance with the obligations of environmental compensation and investment of no less than 1% for the use of water from natural sources, the conservation of biodiversity and its ecosystem services and natural capital targets the areas prioritized by the company by entering into conservation agreements with local communities, among other actions.

2021 Management Efforts

Given the management efforts undertaken in 2021, Ecopetrol is

61% and 41% complaint

with its Biodiversity and Ecosystem Services goals by 2023 and 2030, respectively.

The highlights of the 2021 Management Efforts are28:

161

voluntary conservation

agreements were negotiated to fulfill our environmental obligations together with

166 families

in Colombia. In addition to other actions, these agreements led to the conservation of another 111 ha in 2021, and to the Company conserving and restoring

5,549 ha.

The sustainability of these actions will generate positive impacts on local and regional biodiversity and improve the productive practices of the communities involved.

Natural Climate Solutions: partnerships with TNC, WCS, Fundación Natura, South Pole, and ISA (Conexión Jaguar), with a capture potential of more than

1MtC02/año29.

One (1) Diploma Course and 10 Webinars

on Nature-Based Solutions.

The Company put together three (3) image and sound catalogs of the first three (3) eco reserves created under the initiative with the Humboldt Institute.

Four (4) books

were published with more than

3,000 new records containing genetic information of tropical dry forest species (metabarcoding -Biomoniores-Humboldt), and another four (4) books on Biodiversity and oil, Monitoring in the Colombian Amazon region, the Tropical dry forest, and the Log of the Wildlife Project.

As part of Phase II of the Wildlife Project that Ecopetrol executes in collaboration with WCS,

13 community groups

were created for the conservation of wild species;

116 sustainable productive initiatives were implemented

en 56 predios,

benefiting

383 people; ,

five (5) scientific articles were published in an indexed journal; and 12 environmental criteria were defined in search for a Net Impact on Biodiversity.

Ecopetrol joined the World Economic Forum’s 1t.org initiative to contribute to the protection of biodiversity, and the fight against the impacts of climate change through Nature-Based Solutions.

The Company committed to protect 30,000 ha, offset two (2) MtCO2, and plant 12 million trees by 2030.

Ecopetrol was selected as part of the Taskforce on Nature-related Financial Disclosures (TNFD) initiative to help prepare recommendations to manage risks and opportunities associated with natural capital.

28. This million tCO2 is equivalent to the annual potential of Natural Climate Solutions projects under development to date. The accumulated potential of these projects, taking into account their useful life, is more than 15 million tCO2.

The World Economic Fund’s 1T.Org initiative was presented for the first time at the annual meeting of the World Economic Forum in Davos, Switzerland, in January 2020, as part of the goal established by the United Nations for the restoration of ecosystems between 2021 and 2030. Today, the movement involves more than 30 global companies, including Nestlé, Pepsico, Shell, Mastercard, HP, Eni, Astrazeneca, and others.

Companies that are part of the One trillion trees movement are eligible to join if they have committed to reducing their GHG emissions in line with the Paris Climate Agreement or have set a “carbon neutrality” or “net zero emissions” goal by the end of 2050, as the Ecopetrol Group did in March 2021.

(304-1) (304-3) (WEF 9)

Ecopetrol does not report operations in protected areas categories I to IV of the International Union for the Conservation of Nature (IUCN).

Protected or restored areas of the habitats (Voluntary)

| Criterion | Unit of measurement | 2018 | 2019 | 2020 | 2021 |

|---|---|---|---|---|---|

| Protected or restored areas of the habitats (voluntary) | |||||

| Trees planted or contributed to communities, environmental authorities, or local governments | # | 75,760 | 138,620 | 462,449 | 367,276* |

| Nurseries established | # | 6 | 8 | 22 | 22 |

| Seedlings produced in nurseries | # | 28,820 | 9,000 | 90,724 | 92,868 |

| Areas planted or in restoration processes | ha | 7,832 | 3,976 | 3,201 | 2,772 |

| Number of protected water sources | # | N/A | N/A | N/A | N/A |

| Conservation agreements signed | # | 9 | 60 | 23 | 21 |

| Hectares managed under conservation agreements | ha | 11,659 | 14,127 | 14,048 | 314 |

| Area in silvopastoral systems | ha | N/A | N/A | N/A | N/A |

| Area in agroforestry systems | ha | N/A | N/A | N/A | N/A |

| Eco-efficient stoves installed | # | N/A | N/A | N/A | N/A |

| Protected areas declared under any conservation mechanism | # | 12 | 15 | 15 | 15 |

| Protected hectares declared under any conservation mechanism | ha | 16,846 | 17,675 | 17,675 | 17,675 |

| Ecological households | # | N/A | N/A | N/A | N/A |

| Photovoltaic systems | # | N/A | N/A | N/A | N/A |

| Apiaries – Meliponaries | # | N/A | N/A | N/A | N/A |

| Intervened hydrographic subzones | # | N/A | N/A | N/A | N/A |

| Kms of protected water bodies | km | N/A | N/A | N/A | N/A |

| New or improved hydrometeorological stations | # | N/A | N/A | N/A | N/A |

| Endangered wild species under conservation processes | # | 10 | 15 | 15 | 15 |

| Number of Eco-reserves | # | 1 | 2 | 6 | 15 |

| Hectares of the Eco-Reserve Network | ha | 128 | 414 | 11,906 | 15,085 |

| Protected or restored areas of the habitats (mandatory) | |||||

| Trees planted or contributed to communities, environmental authorities, or local governments | # | 9,198 | 442,350 | 220,605 | 67,470** |

| Nurseries established | # | N/A | N/A | N/A | 2 |

| Seedlings produced in nurseries | # | N/A | N/A | N/A | 21,122 |

| Areas planted or in restoration processes | ha | N/A | N/A | 5,438 | 5,549 |

| Number of protected water sources | # | N/A | 2 | 92 | N/A |

| Conservation agreements signed | # | N/A | N/A | 29 | 161 |

| Hectares managed under conservation agreements | ha | N/A | N/A | 2,045 | 2,297 |

| Area in silvopastoral systems | ha | N/A | 100 | N/A | 34 |

| Area in agroforestry systems | ha | N/A | 181 | 204 | 22 |

| Eco-efficient stoves installed | # | 235 | 72 | N/A | 5 |

| Protected areas declared under any conservation mechanism | # | N/A | N/A | N/A | N/A |

| Protected hectares declared under any<¿ conservation mechanism | ha | N/A | N/A | N/A | N/A |

| Ecological households | # | N/A | N/A | N/A | N/A |

| Photovoltaic systems | # | N/A | 20 | N/A | N/A |

| Apiaries – Meliponaries | # | N/A | N/A | N/A | N/A |

| Intervened hydrographic subzones | # | N/A | 5 | 2 | 7 |

| Kms of protected water bodies | Km | N/A | 10 | 22 | 31 |

| New or improved hydrometeorological stations | # | N/A | N/A | N/A | N/A |

| Endangered wild species under conservation processes | # | N/A | N/A | N/A | N/A |

| Number of Eco-reserves | # | N/A | N/A | N/A | N/A |

| Hectares of the Eco-Reserve Network | ha | N/A | N/A | N/A | N/A |

| Protected or restored areas of the habitats (consolidated) | |||||

| Trees planted or contributed to communities, environmental authorities, or local governments | # | 84,958 | 580,970 | 682,054 | 434,746 |

| Nurseries established | # | 6 | 8 | 22 | 24 |

| Seedlings produced in nurseries | # | 28,820 | 9,000 | 90,724 | 113,990 |

| Areas planted or in restoration processes | ha | 7,832 | 3,976 | 8,640 | 8,321 |

| Number of protected water sources | # | N/A | 2 | 92 | 0 |

| Conservation Agreements managed | # | 9 | 60 | 52 | 182 |

| Hectares managed under conservation agreements | ha | 11,659 | 14,128 | 16,093 | 2,611 |

| Area in silvopastoral systems | ha | N/A | 100 | N/A | 34 |

| Area in agroforestry systems | ha | N/A | 181 | 204 | 22 |

| Eco-efficient stoves installed | # | 235 | 72 | N/A | 5 |

| Protected areas declared under any conservation mechanism | # | 12 | 15 | 15 | 15 |

| Protected hectares declared under any conservation mechanism | ha | 16,846 | 17,675 | 17,675 | 17,675 |

| Ecological households | # | N/A | N/A | N/A | 0 |

| Photovoltaic systems | # | N/A | 20 | N/A | 0 |

| Apiaries – Meliponaries | # | N/A | N/A | N/A | 0 |

| Intervened hydrographic subzones | # | N/A | 5 | 2 | 7 |

| Kms of protected water bodies | Km | N/A | 10 | 22 | 31 |

| New or improved hydrometeorological stations | # | N/A | N/A | N/A | 0 |

| Endangered wild species under conservation processes | # | 10 | 15 | 15 | 15 |

| Number of Eco-reserves | # | 1 | 2 | 6 | 15 |

| Hectares of the Eco-Reserve Network | ha | 128 | 414 | 11,906 | 15,085 |

Note: In the line of “seedlings produced in nurseries,” the number reported in 2021 is associated with Nurseries and plantings, and it is the first year that this information is broken down for Ecopetrol S.A.

* Although there is a decrease of 95,000 planted trees between 2020 and 2021, during 2021 initiatives related to Natural Climate Solutions were matured that will enable the planting of nearly one million trees (250,000 TNC, 230,000 PVS and 6000,000 Natura) through of three agreements that were signed at the end of the year. The planting of these trees will be reflected in the results presented in 2022 and 2023.

**The reduction in the number of planted trees was due to the fact that the execution of these plantings were subject to the execution schedules presented to the Environmental Authority and approved by it. These schedules had for the years 2019 and 2020, the highest execution figures for the establishment of reforestation or planting. In 2021, according to the schedules, contractual planning activities for restoration programs were carried out, which are expected to be executed in 2022.

The goal for 2021 was four (4) million trees, accumulated as a Group, and the voluntary contribution of 367,276 trees allowed Ecopetrol to exceed that goal.

This last information only corresponds to Ecopetrol S.A., and it is lower than the number in 2020. The figure does not necessarily have to increase every year, although the Group’s goal of six (6) million trees by 2023 and 12 million by 2030 remains the same.

Total number of species on the IUCN Red List and on national conservation lists, whose habitats are located in areas affected by the organization’s operations

| Species | Unit of measurement | 2018 | 2019 | 2020 | 2021 |

|---|---|---|---|---|---|

| Critical hazard | # | N/A | N/A | N/A | 1 |

| Endangered | # | N/A | N/A | N/A | 1 |

| Vulnerable | # | N/A | N/A | N/A | 2 |

| Near threatened | # | N/A | N/A | N/A | 2 |

| Least concern | # | N/A | N/A | N/A | 1 |

- There were seven (7) operational incidents greater than one barrel, totaling 157.8 barrels spilled, affecting water bodies and/or vegetation.

- Fauna and flora were affected in three (3) of the seven (7) incidents.

The species affected in these cases are reported below:

- One (1) Critically Endangered (CR) species, 230 individuals.

- One (1) Endangered (EN) species,

- 30 individuals.

- Two (2) Vulnerable species (VU),

- 11 individuals.

- One (1) Near Threatened (NT) species,

- 80 individuals.

- One (1) Near Threatened (NT) mammal species, 2 individuals.

- One (1) Least Concern (LC) terrestrial habit reptile species, 11 individuals.

The commitment to biodiversity includes the following elements:

Required commitment from own operations and the supply chain to avoid operational activities in the vicinity of World Heritage areas and IUCN Category I-IV protected areas.

Application of the mitigation hierarchy (avoid, minimize, restore, and offset) when operating in areas close to critical biodiversity.

Work with the following external partners to fulfill the commitment:

- Fundación Natura: conservation and restoration of tropical forest ecosystems and freshwater wetlands in the Middle Magdalena region and actions to mitigate GHG emissions.

- WCS and Fondo Acción: focused on implementing conservation actions around 15 species and three (3) landscapes.

- TNC: develops a carbon monitoring protocol for restoration projects.

- Conexión Jaguar Program – ISA: GHG mitigation, biodiversity conservation, community participation.

- Cormacarrena: conservation of forests in the upper and middle basin of the Guayuriba and Metica rivers by means of payments for ecosystem services.

- Alexander Von Humboldt Institute: technical knowledge in socio-ecological planning, biodiversity baselines, and planning and development of eco-reserve networks.

- ANDI: biodiversity conservation in the Andean-Amazonian region.

- South Pole: Natural Climate Solutions and management of the carbon project portfolio for GHG compensation.

In the 2020 report, there were no Natural Climate Solutions goals related to monitored hectares, and the goal of trap cameras for biodiversity monitoring was eliminated upon achieving

100% de compliance.

Ecopetrol has established environmental criteria for the selection of contractors, and in terms of Biodiversity. The Company has 12 criteria intended to minimize the impact on the supply chain, including the following:

In 2022, an assessment will be conducted to define the scope, potential targets, and potential implications of commitments such as Net Zero Deforestation and Net Positive Impact for the operational activities and the supply chain..

Biodiversity Exposure and Assessment

Ecopetrol evaluates its operations to determine the level of exposure of biodiversity in its areas of influence

| Biodiversity exposure and assessment | Number of sites | Area (Hectares) |

|---|---|---|

| Total number of sites and total area used for operational activities | 130 | 2,201,972 |

| Biodiversity impact assessments for sites used for operational activities in the last five years | 130 | 2,201,972 |

| Sites and total area evaluated in the last five years that are remarkably close to critical biodiversity | 4 | 191,72 |

| Sites evaluated that are in close proximity to critical biodiversity with biodiversity management plans | 4 | 191,72 |

Roadmap

Circular Economy

Outstanding

Material Element

Sustainable Development Goals

| Impacted stakeholder groups | Areas responsible for managing the impacts | Ecopetrol segments that generate the greatest impact |

|---|---|---|

| Suppliers | The entire Company | Upstream |

| Associates and Partners | Midstream | |

| Clients | Downstream | |

| Employees | Comercial | |

| Investors | ||

| State | ||

| Society and Community |

Why is the

element material?

Circular economy is a cross-cutting enabler that contributes to the fulfillment of goals associated with the energy transition, the goal of zero net carbon emissions, the reduction of the water footprint, the closing of the materials and waste cycle, and the management of natural capital. This element generates opportunities for growth, innovation, job creation, and the conservation of biodiversity and ecosystem services. Considering the foregoing, and its importance for stakeholders, Circular Economy is an outstanding element for Ecopetrol.

The implementation of the circular economy model allows the Company to:

(i)

Promote efficiency in the use of materials, water, energy, and the recovery capacity of ecosystems.

(ii)

Identify initiatives for the development of new business models with economic, environmental, and social benefits.

(iii)

Promote innovation, technology, and research of new products and services.

How is the material

element managed

The Roadmap for this element includes five (5) lines of action:

Strengthening of skills and knowledge generation

Generate the necessary skills to promote circular economy models in the Company.

Circularity in the supply chain

promotes circular initiatives in the procurement of goods and services and in the relationship with suppliers.

Circular initiatives bank

Identification and follow-up on the circular initiatives of Ecopetrol Group.

Circularity metrics

Implement quantitative and qualitative metrics to measure progress with respect to the Company’s circularity.

Circularity criteria

Allows the incorporation of circularity criteria in operational, financial, commercial, and supply procedures.

How is the material

element evaluated?

As part of the Roadmap, the company establishes goals, management indicators, and milestones to be achieved in the short, medium, and long term. Depending on their relevance, some of these are included in the different instances defined by the company’s HSE management system, such as:

Follow-up on the update of the circular initiatives bank to monitor its progress and implementation status in the different areas of the company.

Calculation of the social, environmental, and economic benefits of the circular initiatives implemented.

Measurement of the participation level of professionals in skill strengthening courses.

Measurement of qualitative and quantitative circularity metrics to determine the Company’s level of maturity regarding this subject.

Monitoring is conducted on a monthly basis in the HSE Vice Presidency Committees and those involving the Vice Presidency of Projects and Drilling. The Vice Presidency of Production’s (VDP) Committee also monitors progress in this regard.

Short, medium,

and long-term goals

and projects

Short term: 0 to 2 years

- Calculation of environmental, social, and economic benefits for 100% of the initiatives implemented.

- Implementation of 100% of circular business and prioritized industrial symbiosis cases.

- Circular economy qualitative and quantitative measurements.

- Incorporation of circular criteria in operating, commercial, financial, and supply procedures.

Medium term : 3 to 5 years

- Implementation of 100% of circular business and prioritized industrial symbiosis cases.

- Strengthening of basic skills for 100% of the selected population.

Long term : longer than 5 years

- Implementation of 100% of circular business and prioritized industrial symbiosis cases.

- Substitution of new raw materials for secondary or renewable materials.

- Strengthening of advanced skills for the selected population.

2021 Management Efforts

Circular initiatives bank

297 initiatives associated with:

- Decarbonization 49%

- Waste 29%

- Water 16%

- Materials 5%

- Biodiversity less than 1%

Strengthening of skills

1,296 workers were trained in the “Introduction to Circular Economy” basic virtual course, and 121 people in intermediate courses on the following topics:

Basic concepts to formulate circular projects

Financial model of circular projects

Systems thinking and application in circular processes

Circularity Criteria

Circularity criteria were included in the guidelines of the Vice Presidency of Projects and Drilling to include sustainable eco-designs in engineering projects, from the conceptual to the detailed phase. This, in order to mitigate environmental impacts and contribute to the closing of cycles, in line with the principles of circular economy and the decarbonization, water, biodiversity, and waste goals, among others.

Circularity in the supply chain

The implementation of the circular economy model in the supply chain in 2021 led to the following results:

- Materials showcase and lending: platform to post the materials no longer required by Ecopetrol, also accessible by subsidiaries.

- Buy back: incorporation of a model, in the procurement planning phase, to offer the possibility to repurchase the asset once its useful lifespan has expired. This avoids waste and generates income from the sale of the asset once it is no longer required. These revenues amounted to COP 6.9 million in the 2018-2021 period.

- Chemical Leasing: In September, UNIDO (United Nations Industrial Development Organization) recognized Ecopetrol as a leading Company in the implementation of Chemical Leasing, which consists of shifting from the purchase to the payment for service of chemical products.

The certification was obtained by presenting the financial and environmental benefits of the catalyst procurement strategy for the Cartagena Refinery, and the chemical treatment strategy for the Cartagena Refinery and the Apiay Operations Management. - Reincorporation of waste in infrastructure: First contractual model for ferrous waste to be used by a third party as raw material for infrastructure works at Ecopetrol S.A. warehouses.

- Green Clause: 27 updated clauses and incorporation of environmental criteria for the selection of partners in engineering, operation, and maintenance strategies and refining chemical treatments.

- Circular initiatives in food: use of the wasted arising from food preparation at the cafeterias for composting or vermiculture purposes. Analytics in production forecasts, among others, to use 83% of this waste throughout the country.

Circularity maturity level

By means of this line of action, Ecopetrol will periodically assess the implementation progress of the Circular Economy Model using qualitative and quantitative metrics.

(i)

Qualitative: internally establishes the level of circularity maturity by determining to what extent the principles of circular economy (systems thinking, innovation, responsible management, collaboration, value optimization, and transparency), are implemented throughout the Company’s current decisions and activities.

(ii)

Semi Qualitative-Quantitative: external measurement to report information in a standardized manner and with a score to measure progress and understand where the Company is in the transition towards a circular economy, by comparing itself with other companies.

(iii)

Quantitative: framework of indicators based on an evaluation of the flow of materials with other indicators related to resource efficiency and effectiveness, economic investment, and technological incorporation in circular initiatives.

In this sense, the following standards were defined as circularity metrics to start gradually and progressively measuring them as of 2021.

Circularity metrics

| Qualitative | Semi Qualitative – Quantitative | Quantitative |

|---|---|---|

This measurement will be taken using the GTC 314:2020 standard (which corresponds to an identical adoption of the BS8001-2017 standard) enacted by ICONTEC in November 2020.  | Circulitycs was selected for this measurement, which is a tool developed by the Ellen MacAthur Foundation, a pioneer in Circular Economy.  | Mix of indicators according to different standards (e.g.: WBCSD, Ellen MacArthur Foundation, ISO 59020, or others). |

Below are the results for 2021:

1

Preparation of the first qualitative measurement of circular economy, whose results rank Ecopetrol at Level 3 (Committed) according to Colombian Technical Guide (GTC, by its Spanish acronym) 314:2020. The measurement scale comprises four (4) levels, where zero (0) is the basic level of legal compliance and level four (4) is the highest, in which companies innovate in their business model and in the ways they create value.

2

Based on this measurement, a work plan is structured to close gaps with the operational and support areas.

3

The percentage of circularity of the materials used in catering contracts was calculated, with a circularity of 70%; and the transformation of ferrous waste, with 50%. The international reference guide used was the Circular transition indicators v2.0 – Metrics for business by business of the World Business Council for Sustainable Development (WBCSD).

4

Bituminous material (MBL, by its Spanish acronym) from sludge or oily residues as asphalt binder for the improvement of low-traffic roads. In 2021, Ecopetrol received the Phase I results from the research currently underway with the UIS, with promising laboratory results to produce MBL bituminous materials for the construction of road surface improvement layers.

Out aspiration in 2022 is to conduct the Semi – Qualitative – Quantitative measurement using the methodology of the Ellen MacArthur Foundation with Circulytics.

Use of energy and

alternative sources

Outstanding

Material Element

Sustainable Development Goals

| Impacted stakeholder groups | Areas responsible for managing the impacts | Ecopetrol segments that generate the greatest impact |

|---|---|---|

| Suppliers, contractors, and their workers | VCM | Upstream |

| Clients | VDS | Midstream |

| Investors and Shareholders | VRP | Downstream |

| National State | VDP | Comercial |

| Local State | ||

| Society and Communities |

Why is the

element material?

The use of energy and alternative sources responds to the identified expectations of stakeholders and global trends, which is part of the Growing in the Energy Transition and Generating Value with TESG pillars of the 2040 Strategy.

How is the material